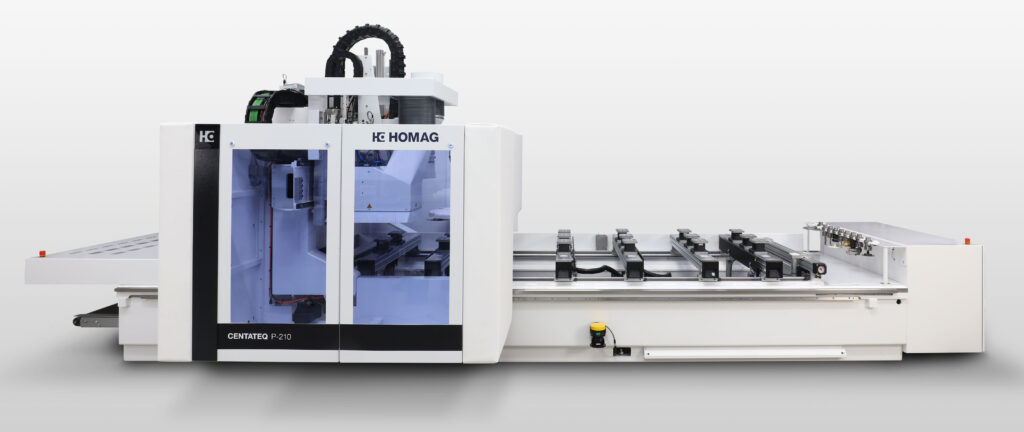

Baumgarten Bootsbau is expanding its production hall by 400m² this year to accommodate the new 5-axis CNC machining center.

This CNC machine not only increases production productivity, but also significantly accelerates the production of newly developed boat moulds.

In contrast to the existing 3-axis CNC milling machine, the new system can not only process wood and carbon, but also aluminum, which opens up completely new production possibilities.

CNC machines (Computerized Numerical Control) are machine tools that, through the use of control technology, are able to automatically produce workpieces with high precision, even for complex shapes.

Modern CNC machines can already have more than six processing axes, with the fourth to sixth axes (A, B, C) each representing a rotation around the main axis (X, Y, Z) and being referred to as the auxiliary axis.

When using CNC machines, there is often no need for constant supervision of the production by auxiliary personnel, in many series production only a few people are used directly on the machines, since the controls offer sufficient possibilities to even fully automatically integrate quality control into the manufacturing process. Tool wear and breakage is also monitored fully automatically.